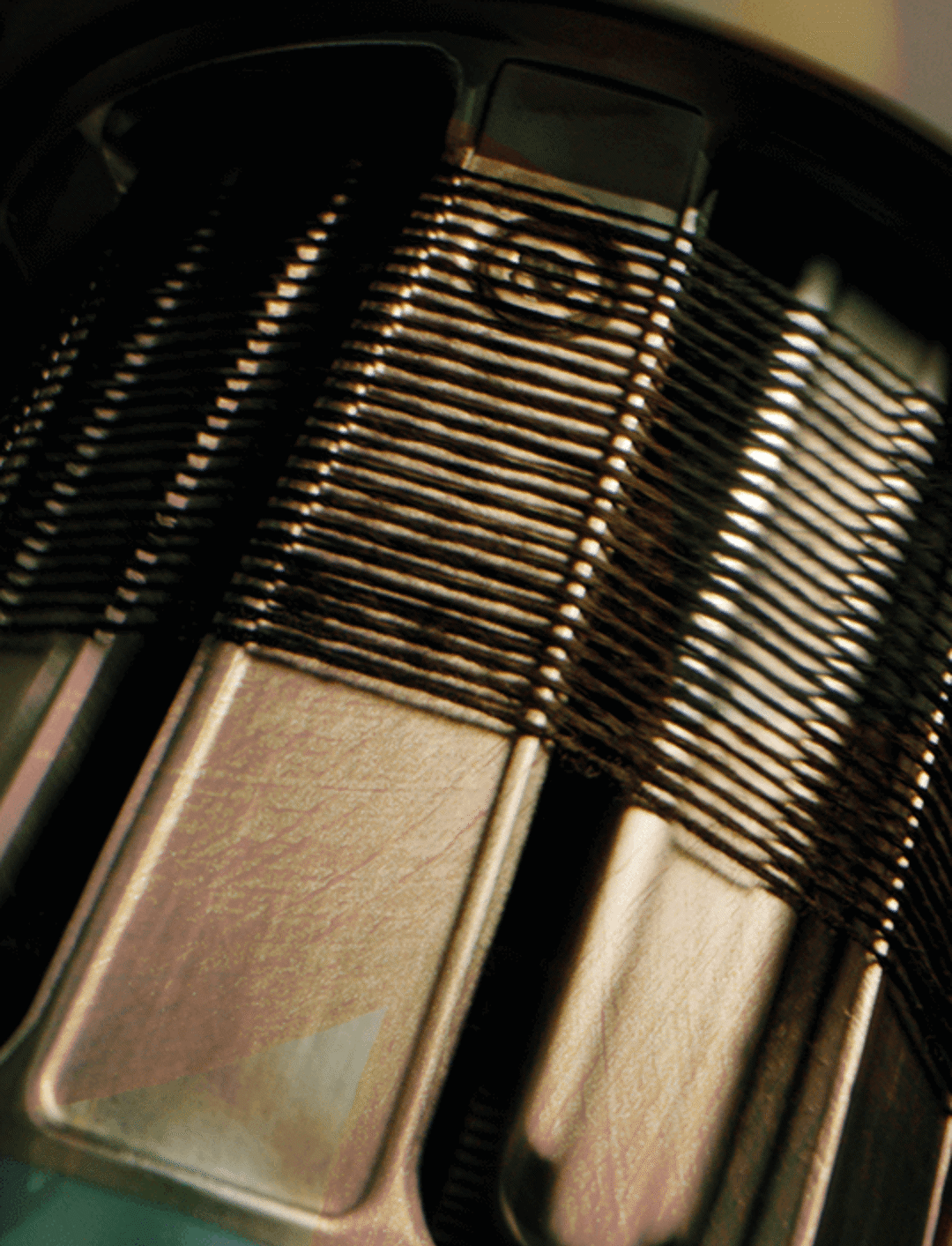

An innovative concept, each ShrinKnit fabric or mesh is knitted to a larger dimension than a chair's frame. Once manufactured, it is free from tension and can be upholstered with incredible ease as a result of this give – able to be applied by staples, Kadar strips or zips.

Following its application, the knitted fabric is shrunk by radiant heat, hand upholstery steamer, or an oven – creating the reduction in size which provides the perfect tension, and perfect fit. The heat must be between 100C and 115C and applied for just 10 – 12 seconds, creating chairs which are ergonomically superior and aesthetically striking in minimal time.

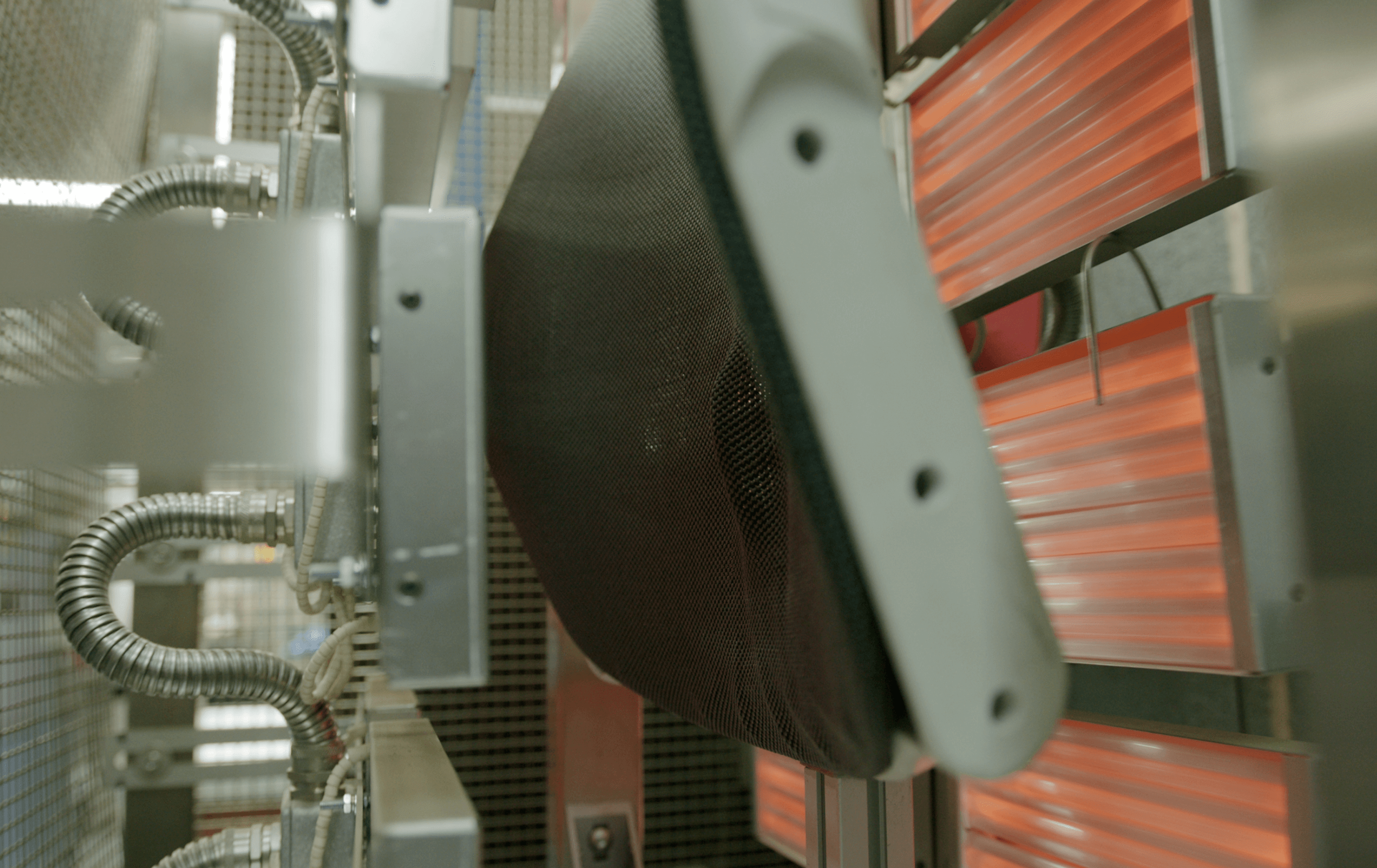

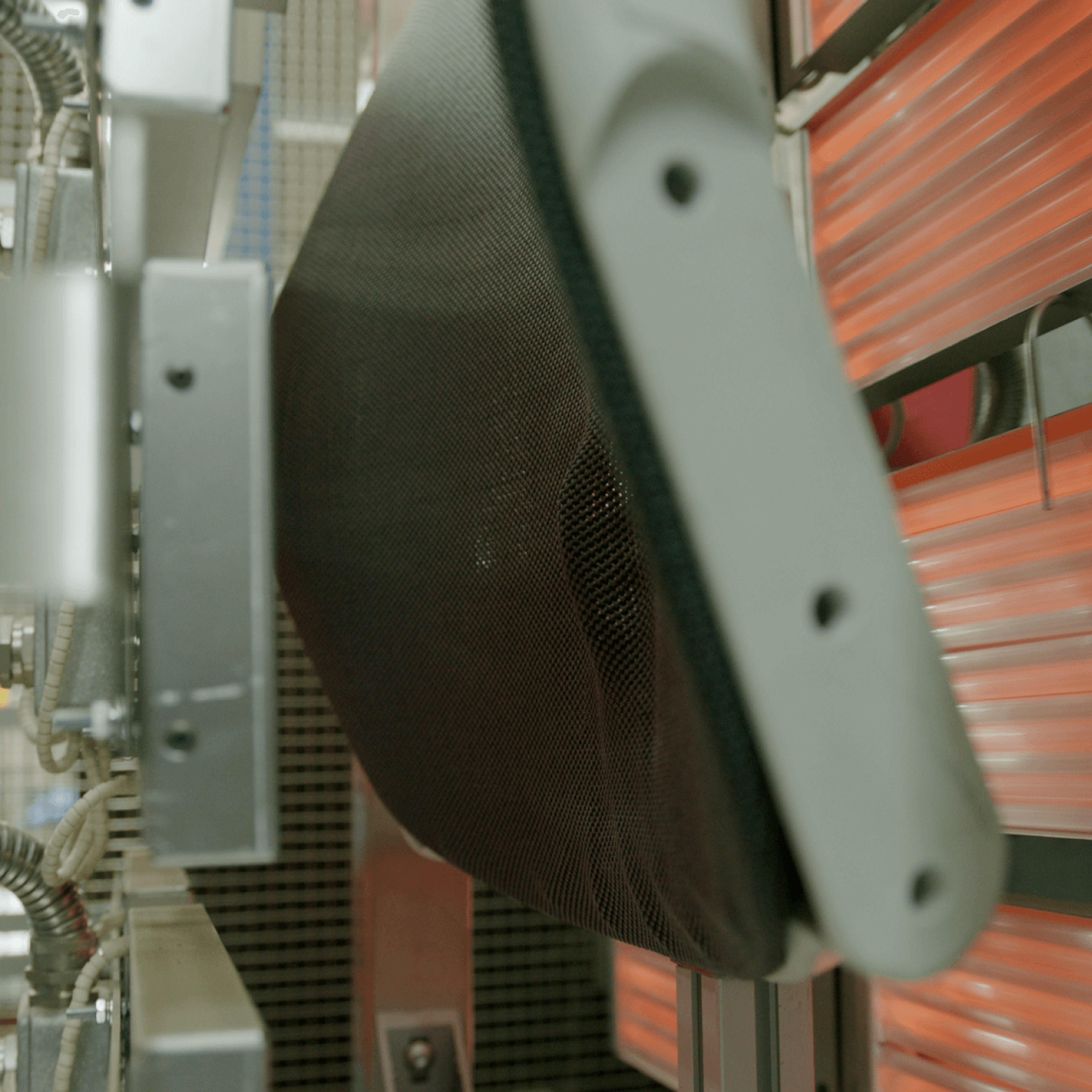

For mass produced chairs featuring ShrinKnit, we are able to work in conjunction with thermal engineers to build bespoke heating equipment which provide commercial level processing.

Following its application, the knitted fabric is shrunk by radiant heat, hand upholstery steamer, or an oven – creating the reduction in size which provides the perfect tension, and perfect fit. The heat must be between 100C and 115C and applied for just 10 – 12 seconds, creating chairs which are ergonomically superior and aesthetically striking in minimal time.

For mass produced chairs featuring ShrinKnit, we are able to work in conjunction with thermal engineers to build bespoke heating equipment which provide commercial level processing.